Bumpgate: Difference between revisions

More revisions; added a couple more citations. Planning to clean up the in-text citations a little more at some point. |

m Fixed line break that caused error. |

||

| Line 9: | Line 9: | ||

These manufacturers had engineered GPUs that electrically connected the silicon chip (die) to the substrate (the "green square part") using high-lead solder bumps. High-lead solder bumps were chosen in order to fit the power delivery specifications that these GPUs needed.<ref>{{Cite web |last=Williams |first=Rob |date=29 Sep 2008 |title=NVIDIA at a Disadvantage Due to their Choice of Solder? |url=https://techgage.com/news/nvidia_at_a_disadvantage_due_to_their_choice_of_solder/ |url-status=live |access-date=1 Jun 2025 |website=Techgage}}</ref> To give these solder bumps more strength (especially when operating at high temperatures), it's standard to use an epoxy with silica filler known as underfill. Underfill needs to fit certain specifications, depending on how hot the processor it's used on is expected to get. If it's too hard, the underfill will crack the die. If it's too soft, the bumps will crack because the underfill isn't supportive enough. It also needs to still fit within the right specifications at both high and low temperatures. | These manufacturers had engineered GPUs that electrically connected the silicon chip (die) to the substrate (the "green square part") using high-lead solder bumps. High-lead solder bumps were chosen in order to fit the power delivery specifications that these GPUs needed.<ref>{{Cite web |last=Williams |first=Rob |date=29 Sep 2008 |title=NVIDIA at a Disadvantage Due to their Choice of Solder? |url=https://techgage.com/news/nvidia_at_a_disadvantage_due_to_their_choice_of_solder/ |url-status=live |access-date=1 Jun 2025 |website=Techgage}}</ref> To give these solder bumps more strength (especially when operating at high temperatures), it's standard to use an epoxy with silica filler known as underfill. Underfill needs to fit certain specifications, depending on how hot the processor it's used on is expected to get. If it's too hard, the underfill will crack the die. If it's too soft, the bumps will crack because the underfill isn't supportive enough. It also needs to still fit within the right specifications at both high and low temperatures. | ||

In 2006, IBM and Amkor published a study that explained that use of a low T<sub>g</sub> underfill was not acceptable with high-lead solder bumps, and high T<sub>g</sub> would be necessary to avoid defects.<ref>{{Cite journal |last=Ray |first=S. |last2=Kiyono |first2=S. |last3=Waite |first3=K. |last4=Nicholls |first4=L. |date=2006 |title=Qualification of low-K 90nm Technology Die with Pb-free Bumps on | In 2006, IBM and Amkor published a study that explained that use of a low T<sub>g</sub> underfill was not acceptable with high-lead solder bumps, and high T<sub>g</sub> would be necessary to avoid defects.<ref>{{Cite journal |last=Ray |first=S. |last2=Kiyono |first2=S. |last3=Waite |first3=K. |last4=Nicholls |first4=L. |date=2006 |title=Qualification of low-K 90nm Technology Die with Pb-free Bumps on a Build-up Laminate Package (PBGA) with Pb-free Assembly Processes |journal=56th Electronic Components and Technology Conference |pages=139-144 |via=IEEE}}</ref> Therefore, because Nvidia and ATI chose to use high-lead solder bumps, they needed a high T<sub>g</sub> underfill. However, this study was not out at the time that GPUs from 2005 were made, and the companies ended up using low T<sub>g</sub> underfill in these processors. | ||

a Build-up Laminate Package (PBGA) with Pb-free Assembly Processes |journal=56th Electronic Components and Technology Conference |pages=139-144 |via=IEEE}}</ref> Therefore, because Nvidia and ATI chose to use high-lead solder bumps, they needed a high T<sub>g</sub> underfill. However, this study was not out at the time that GPUs from 2005 were made, and the companies ended up using low T<sub>g</sub> underfill in these processors. | |||

This low T<sub>g</sub> underfill would become too soft at high, but normal operating temperatures for these GPUs. When the processor went through normal thermal changes, the solder bumps would soften under heat and harden as they cooled.<ref name=":0">{{Cite web |last=Demerjian |first=Charlie |date=1 Sep 2008 |title=Why Nvidia's chips are defective |url=http://www.theinquirer.net/inquirer/news/1004378/why-nvidia-chips-defective |url-status=dead |archive-url=https://web.archive.org/web/20090520152257/http://www.theinquirer.net/inquirer/news/1004378/why-nvidia-chips-defective |archive-date=20 May 2009 |access-date=1 Jun 2025 |website=The Inquirer}}</ref> This would happen over and over again until they cracked under the thermal stress. When enough solder bumps cracked, it would cause a failure in the unit, hence the term "Bumpgate". | This low T<sub>g</sub> underfill would become too soft at high, but normal operating temperatures for these GPUs. When the processor went through normal thermal changes, the solder bumps would soften under heat and harden as they cooled.<ref name=":0">{{Cite web |last=Demerjian |first=Charlie |date=1 Sep 2008 |title=Why Nvidia's chips are defective |url=http://www.theinquirer.net/inquirer/news/1004378/why-nvidia-chips-defective |url-status=dead |archive-url=https://web.archive.org/web/20090520152257/http://www.theinquirer.net/inquirer/news/1004378/why-nvidia-chips-defective |archive-date=20 May 2009 |access-date=1 Jun 2025 |website=The Inquirer}}</ref> This would happen over and over again until they cracked under the thermal stress. When enough solder bumps cracked, it would cause a failure in the unit, hence the term "Bumpgate". | ||

Revision as of 08:05, 16 June 2025

Bumpgate, also known as Nvidiagate, was a scandal where Nvidia and ATI Graphics Processing Units (GPUs) were prone to high failure rates due to a design flaw that led to cracked solder bumps under the die.[1] Despite the "Nvidiagate" name, this defect not only affected many Nvidia GPUs made from approximately 2006 to 2010, but it also affected ATI GPUs from 2006 to 2008. Among retro console enthusiasts, the defect is best known to have been the likely culprit behind the high failure rate of Nvidia GPUs in Sony's early PlayStation 3 models[2] and ATI GPUs in Microsoft's early Xbox 360 models.[3] Individuals interested in other retro computers may know of the defect from certain models of Dell and HP laptops manufactured as early as 2005 and as late as 2010, as well as certain Apple Macbook Pros made from May 2007 to September 2008.[4]

Background

Graphics Processing Unit (GPU) Faults

From approximately 2005-2010, GPU manufacturers Nvidia and ATI developed some GPUs that had a serious design flaw. This flaw led to failures in many of their GPUs during that time period, and Nvidia even saw a class action lawsuit from it. In order to understand what truly happened during this controversy, though, it's important to understand what exactly led to the faults.

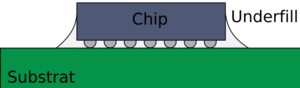

These manufacturers had engineered GPUs that electrically connected the silicon chip (die) to the substrate (the "green square part") using high-lead solder bumps. High-lead solder bumps were chosen in order to fit the power delivery specifications that these GPUs needed.[5] To give these solder bumps more strength (especially when operating at high temperatures), it's standard to use an epoxy with silica filler known as underfill. Underfill needs to fit certain specifications, depending on how hot the processor it's used on is expected to get. If it's too hard, the underfill will crack the die. If it's too soft, the bumps will crack because the underfill isn't supportive enough. It also needs to still fit within the right specifications at both high and low temperatures.

In 2006, IBM and Amkor published a study that explained that use of a low Tg underfill was not acceptable with high-lead solder bumps, and high Tg would be necessary to avoid defects.[6] Therefore, because Nvidia and ATI chose to use high-lead solder bumps, they needed a high Tg underfill. However, this study was not out at the time that GPUs from 2005 were made, and the companies ended up using low Tg underfill in these processors.

This low Tg underfill would become too soft at high, but normal operating temperatures for these GPUs. When the processor went through normal thermal changes, the solder bumps would soften under heat and harden as they cooled.[1] This would happen over and over again until they cracked under the thermal stress. When enough solder bumps cracked, it would cause a failure in the unit, hence the term "Bumpgate".

Companies involved and responses

Bumpgate was a worldwide issue for any consumer that purchased these defective graphics processors. However, it's not fully clear who was the most responsible for the incident. Building a GPU is a specialized process that requires it to go through multiple partner companies before ultimately ending up with the company that sells the unit (i.e., Microsoft, Sony, Nvidia, etc.). With this in mind, it is still important to note the response of each of the companies that were the public faces involved in this incident.

Microsoft's Response - The "Red Ring of Death"

"The breakthrough came when we understood that the connections that were being broken were not located on the motherboard, but they were actually located inside the components." - Leo Del Castillo, member of Xbox's hardware engineering group; Power On: The Story of Xbox (2021)[3]

In November 2005, Microsoft released the Xbox 360 with the ATI Xenos GPU. According to leaked internal Microsoft documents from the time, 1.2 million 360s shipped out to consumers by November 30th, 2005. 3% of customers had some type of issue with their system. Out of that 3%, 19% had three flashing red rings, and 24% had freezing problems.[7]

Therefore, 43% of consumers shortly after launch had these familiar symptoms to retro console enthusiasts: the "Red Ring of Death"- which is what consumers around the world called the Xbox 360's Bumpgate-related fault. However, "three flashing red rings" on the Xbox 360 simply means "core digital error"- in other words, a general hardware failure. It takes multiple power-on cycles to cause a failure in the solder bumps, so it is unlikely that these systems were failing specifically because of the Bumpgate defect. 56% of systems worked on the first try, and after component reworks, that number improved to 71%. Only 200,000 consoles went to what Microsoft termed "the bonepile", a collection of broken consoles that still did not work after a component rework. However, it is also worth noting that some owners discovered that some afflicted Xbox 360s will work again after a "reflow"- which is effectively redoing all of the components on the motherboard at once. In addition, Microsoft wasn't aware that the "Red Ring of Death" was a specific widespread problem yet, so they would not have been taking major note of consoles with a GPU problem. At the height of the Bumpgate-related defect, approximately 600,000 to 1,000,000 Xbox 360s were suffering from the "Red Ring of Death".

For several months, Microsoft had consumers pay to repair their consoles. However, in 2007, they chose to extend the warranty for Xbox 360 consoles displaying an E74 error (an on-screen error also associated with "Red Ring of Death") from one year from date of purchase, to three years from date of purchase. This allowed most consumers who had consoles with the issue to get their consoles refurbished. In addition, they refunded any consumers who had paid to have their afflicted systems repaired.[8]

Microsoft primarily seemed to have done this to protect the Xbox brand. The Xbox 360 was only their second console, and the original Xbox hadn't done as well as they'd hoped it would. Microsoft confirmed this in Chapter 5 of their 2021 documentary, Power On: The Story of Xbox.[3]

By mid-2008, the cause of the issue was confirmed to be "within the components"- the low Tg underfill. ATI and Microsoft completely fixed the issue in Xbox 360s made after this point. Generally, it is recommended by retro console enthusiasts to purchase consoles manufactured after May 2008 (or marked "Q2 2008") and avoid consoles manufactured before this point, but the Tonasket (AKA "Jasper Kronos" or "Jasper V2") motherboard revision is generally considered to be the most reliable of the original "phat" model Xbox 360 consoles.[9]

Sony's Response - The "Yellow Light of Death"

"We entirely refute the suggestion that PS3 consoles have an inherent defect or other design issue which is akin to any warranty issue experienced by another console manufacturer. [...] We think it is highly unfair to suggest that from an installed base of 2.5 million that the numbers you mention somehow are evidence of a 'manufacturing defect'..." - Ray Maguire, managing director and senior vice president of Sony Computer Entertainment Europe in 2009; in a letter responding to a BBC Watchdog segment covering the "Yellow Light of Death".[10][11]

In November 2006, Sony released the PlayStation 3. Like the Xbox 360, the early models of PlayStation 3 had what consumers believe to be Bumpgate-related issues with its Nvidia-based RSX GPU. Many consumers who had bought launch models- what are now commonly known as "PlayStation 2 backwards compatible" models- found that their systems were malfunctioning. PlayStation 3 systems that were exhibiting the issue may freeze suddenly during gameplay and shut off, but all users who dealt with the defect had a common experience: when attempting to turn their PlayStation 3 on, the LED power indicator would turn green for a moment, then the system would beep three times, very briefly flash to a yellow light, then it would continuously blink red without booting the system. This was coined by consumers as the "Yellow Light of Death".

BBC Watchdog aired a segment in 2009 covering the "Yellow Light of Death".[12] The hosts stated that when viewers called Sony because their console was malfunctioning, Sony told them that it could have been for a variety of reasons, and they couldn't determine exactly what the problem was without disassembling the console having the issue. While all of this is true- the LED indicators do simply indicate a general hardware failure that requires troubleshooting by connecting to the System Controller (Syscon) and checking for error codes- it is worth noting that by August 2008, Sony was building consoles with the 65nm RSX[13][14], which has been confirmed by enthusiasts to not suffer from the theoretically Bumpgate-related fault.[7][15]

Sony never issued a recall or extended warranty for these systems; all consumers had to pay out of their own pocket if they wanted their consoles repaired, unless the system failed during the standard one-year warranty period. However, that was rare; the PS3's fan table accommodated better for the temperature changes than the Xbox 360 did, so it took longer for the defect to break the console. Depending on how frequently the console was used, some consumers could have had their console for a few years before it displayed symptoms. However, for a console that was advertised to still be relevant "ten years [from release]", a few years was not an acceptable lifespan.

According to one of the individuals interviewed in BBC's Watchdog segment, if the system was outside of its one year warranty period, they would have to pay £128 (~$173) to get the system fixed, and they would only provide customers with a three-month post-repair warranty. If it failed again after that point, they would have to pay out of pocket again. Keeping in mind that the fault was very likely caused by a GPU defect, this possibility was very likely unless Sony's repair technicians replaced the defective 90nm GPU with a non-defective one, which they were able to do for some consoles.[16][17] In addition, the console would also be reset during the repair, meaning that the owner would lose all data that was not backed up prior to the failure, such as game saves.[12]

Instead of admitting that there was a defect and issuing an extended warranty to consumers (like Microsoft did) Sony simply quietly fixed the defect around the same time that Microsoft did for the Xbox 360, so PS3 "slim" revisions and newer were not affected. Specifically, it was only 90nm GPUs that appeared to have low Tg underfill- and hence, the defect. As of 2025, Sony has still never made a statement confirming that "Yellow Light of Death", their theoretically Bumpgate-related issue, was a widespread problem in early PlayStation 3 models. The only reason that consumers know that the RSX was likely afflicted by Bumpgate is thanks to console repair and modding enthusiasts- who had to do extensive research to find out the true cause of the problem. It was clear from the timeline of what systems have been observed to be reliable or unreliable revisions,[2][18] as well as tests performed by console repair and modding enthusiasts,[15] that this was a Bumpgate-related defect.

Dell's and HP (HP-Compaq)'s Responses - BIOS Updates and Free Repairs

There were a variety of Dell and HP-Compaq notebook laptops that were affected by the Bumpgate defect, as evidenced by the Nvidia class action lawsuit.[4] Upon being informed of the defect by Nvidia in 2008, both companies distributed BIOS updates for affected systems with Nvidia GPUs that according to The Inquirer, "[ran] the fan all the time".[19] The purpose of this was to attempt to prevent the problem from occurring so that consumers wouldn't have to get their systems repaired. However, both companies also provided free repairs for systems already exhibiting symptoms of a failing GPU, such as no video output to the monitor or the computer failing to boot. It's implied in an SEC report that Nvidia filed in 2008 that the companies were compensated for providing this service.[20]

Both Dell and HP-Compaq also offered varying limited warranties after impacted devices were repaired. HP-Compaq offered a limited warranty for 24 months (two years) after the start of customers' original limited warranty or 90 days (approximately three months) after the affected notebook was repaired- whichever was later.[21] Dell extended limited warranties for systems with these issues for 12 months (one year) from the original purchase date, with a maximum of up to 60 months (five years). In addition, they even offered this to customers whose original warranties already expired- making the new warranty valid from the date the original warranty expired.[22][23]

Apple's Response - Macbook Pro, May 2007 - September 2008

In May 2007, Apple released a version of the aluminum Macbook Pro that used the Nvidia GeForce 8600M GT GPU, and manufactured the computers with this GPU until September 2008. They stopped manufacturing them with this GPU because they discovered it was one of the models affected by Bumpgate. Unlike the issues with the PlayStation 3 and Xbox 360 where the system wouldn't even boot, consumers ran into distorted video or no video output on their devices. Nvidia had assured Apple that the graphics processors were not defective, so Apple initially ignored reports expressing that possibility.[24][25] However, after doing their own investigation, Apple had found that the processors were indeed defective. Because of this, Apple offered extended repair coverage adding up to four years from the date of original purchase, and refunded customers who already paid to repair systems affected by this defect.[26]

Nvidia's Response - Inquirer Accusations and SEC Report

See also: Lawsuit(s)

[As of July 2, 2008, all] newly manufactured products and all products currently shipping in volume have a different and more robust material set. [...] We intend to fully support our customers in their repair and replacement of these impacted MCP and GPU products that fail. - Marvin Burkett, Nvidia Chief Financial Officer, Form 8-K report to SEC.[20]

Nvidia processors were not the only ones affected by the Bumpgate defect (i.e., the Xbox 360's ATI Xenos GPU), but they seem to have been the most heavily impacted. There were a wide variety of Nvidia graphics processors across multiple architectures that had this defect, but according to the class action lawsuit settlement,[4] the earliest confirmed system with the defect appears to have been manufactured in December 2005, and the latest systems were manufactured in late February 2010.

The defects were being noticed broadly amongst consumers around July 2008, particularly when The Inquirer published reports that drew attention to the problems.[27][19] Charlie Demerjian, writer for The Inquirer, firmly presented claims and evidence that every G84 and G86 GPU was defective- including desktop GPUs- even accusing Nvidia of attempting to cover up the problems.

On July 2nd, 2008- a few days before Demerjian's article was published- Nvidia filed a report with the Securities and Exchange Commission (SEC).[20] The report explained that the corporation would pay a $150-200 million one-time charge to cover customer warranties, repairs, returns, replacements, and other notable expenses caused by poor packaging material in some of their media and communications processors (MCPs) and GPUs exclusively used in laptops. This report also confirmed that all of their newly manufactured products from that point forward would have a more suitable material set.

As Joel Hruska from Ars Technica explained, if Nvidia was trying to cover up the defect- as Demerjian claimed- with this report to the SEC, they not only attempted to avoid responsibility and accused their suppliers of causing the problem, they also committed financial fraud by intentionally lowballing their expected financial losses. This is a major accusation that could have had severe consequences for Nvidia.[28] However, it is difficult to verify if Nvidia was lying or simply not fully aware of the scale of Bumpgate. Nvidia's public acknowledgement of the defect in the SEC report is consistent with when Sony switched the PlayStation 3 to the non-defective 65nm RSX (based on an Nvidia chipset),[13] and it also seems to be consistent with when Dell[23] and HP[21] discovered the problem. The only company it does not appear consistent with is Apple, who discovered the defect in their Macbook Pro systems after their own investigation in September 2008.[24] Even so, it is possible that Nvidia did not know that the GeForce 8600M GT GPUs in the 2007-2008 Macbook Pro were impacted yet when Apple asked them about it, because the situation was still developing.

Regardless of if Nvidia was truthful in their report or not, they denied the claims that individuals like Demerjian were making- that all of their GPUs were defective and failing en masse.[28] However, by 2010, consumers' trust in Nvidia had eroded to the point that a class action lawsuit was filed because of the defect.

Nvidia Class-Action Lawsuit (2010)

In 2008, individuals and companies began filing lawsuits against Nvidia. A total of nine cases were filed that were found to be related, and by 2010, these became a class-action lawsuit.

Claims

Class members claimed that Nvidia had manufactured defective GPUs and knowingly failed to compensate them.

Main claims of the suit.

Rebuttal

Nvidia denied all allegations of wrongdoing and tried to defend their actions.

The response of Nvidia or counterclaims.

Outcome - Settlement and Class Member Appeal

Nvidia opted for a settlement[29]- though, asserted that the settlement was not an admission of wrongdoing. Consumers who participated as settlement class members were presented with three options to be compensated, with all benefits paid for by Nvidia:

- A replacement GPU inside their affected notebook;

- A replacement HP notebook computer with one "similar in kind and value" to the one they owned;

- Reimbursement of either the whole cost of repairing the notebook due to a previous GPU failure or a portion of that amount (dependent on how many people submitted valid claims for reimbursement).

The majority of people got their notebooks repaired, but some HP laptops could not be repaired, so they had to be replaced. Many of the systems eligible for the settlement were high-end laptops, originally valued around $1,000 USD. Unfortunately, they were given a budget Compaq Presario CQ56 that was not equivalent in specifications or original value, because it costed approximately how much the three-year-old, defective laptops they replaced were valued at by the time the settlement was reached. Outraged, some of those Class Members contacted Ted Frank from the Center for Class Action Fairness, who promptly filed a complaint with the court to appeal. However, US District Chief Judge James Ware ruled in Nvidia's favor, because the Compaq Presario CQ56 "[came] with an advanced operating system, new warranty and other programs".[30]

Consumer response

[Summary and key issues of prevailing sentiment from the consumers and commentators that can be documented via articles, emails to support, reviews and forum posts. General Consumer Response (frustration at/satisfaction with Microsoft, Sony, etc.)]

Xbox 360/Microsoft Consumer response

At first, consumers were angry at Microsoft. During the months that the company would not acknowledge the widespread "Red Ring of Death", many consumers felt as if they'd been tricked and made a bad investment when they purchased an Xbox 360. However, when Microsoft extended the warranty on Xbox 360s experiencing an E74 error to three years after purchase, consumer sentiment improved. After Microsoft's explanation and confirmation of the exact issue that caused the "Red Ring of Death" in Power On: The Story of Xbox,[3] many consumers who remembered dealing with this issue felt further validated, restoring some trust in Microsoft and the Xbox brand. The release of this information also helped enthusiasts learn more about how to fix the issue not only in early Xbox 360s, but even in Sony's early PlayStation 3 systems- as this helped to elucidate the true cause of the early PS3s' problems.

PlayStation 3/Sony Consumer Response

Consumers who experienced the "Yellow Light of Death" were upset with Sony for their poor response. Some, such as PS3 modding and repair enthusiast "RIP Felix", described Sony's response as "gaslighting"[7]- saying that Sony had manipulated consumers into thinking that there was no widespread defect. The six-page letter from Ray Maguire to the BBC following their Watchdog segment takes a tone that supports Felix's claim[10][11]; By 2009, Sony had stopped producing PS3s with the defective 90nm RSX- which left many consumers suspicious that Sony was trying to cover up the problem to avoid taking responsibility for it.

In 2006, when the PlayStation 3 was new, the console costed $599 USD for the 60GB model ($499 USD for the 20GB model).[3] This was a major price to pay for a game console; the Nintendo Wii launched at $249.99 USD in November 2006,[31] and the Xbox 360 launched in late November 2005 at $399 USD ($299 USD for the Core System version).[32] Because of the extremely high price compared to competitors, consumers felt that they were making a major investment in a high quality system that would be well-supported if there was a defect. Instead, Sony refused to acknowledge the "Yellow Light of Death", denied how widespread it was in their only official rebuttal, and made consumers pay for an issue that was never their fault. Some consumers who dealt with the "Yellow Light of Death" paid Sony to repair their systems, but others decided to simply consider it a loss. For consumers whose systems failed after the "Slim" models came out, some of them chose to re-purchase the cheaper, allegedly more reliable Slim models. At the time, it was assumed that these models were not prone to "Yellow Light of Death" (they have since been confirmed completely non-defective), but there was still some uncertainty among the community at the time. However, others gave up on Sony entirely, switching to other platforms- particularly, the Xbox 360.

As a result of the poor response from Sony, consumers largely took things into their own hands. When the PS3 was still supported, informed consumers were sure to warn prospective buyers that the "backwards compatible" and "phat" models of PS3 were prone to the "Yellow Light of Death", that Sony wouldn't fix it for free, and even if they were willing to send it in for repairs, the system would be reset. In the United Kingdom, there was the BBC Watchdog segment that- while misguided on the cause of the problem- did inform consumers across the UK about the issues, so they knew to avoid these early PS3s and choose a newer Slim model if they wanted a PS3.

As of 2025, nearly every consumer knows about the reliability issues of the early, "backwards compatible" PlayStation 3s. Despite this, though, these systems are quite popular among retro console repair and modding enthusiasts particularly for their ability to play not only original PlayStation games, but also PlayStation 2 games. The earliest two revisions, CECHAxx and CECHBxx, even have real PlayStation 2 processors built-in.[18] This is especially enticing to consumers who own a PlayStation 5, which is capable of playing PlayStation 4 games, so a person could play any PlayStation game across any generation on legitimate hardware with only two consoles. Of course, the reliability issues of these early PS3s is a major downside, so the community has been looking for ways to permanently repair these systems for nearly two decades. In recent years, a breakthrough was made with the discovery of officially repaired early PS3s by transplanting a non-defective 65nm or 45nm RSX into the consoles,[16] and the subsequent development of the "Frankenstein Mod" that is effectively the same procedure made possible for enthusiasts.

Nvidia Consumer Response

Many consumers were uncomfortable with purchasing Nvidia's products for several years, because they saw Nvidia as untrustworthy after their perceived response to the Bumpgate scandal. A GPU is one of the most expensive components in a computer, and it's an investment expected to last for approximately as long as the component remains technologically relevant. Therefore, consumers had some right to be cautious when hearing about defective Nvidia GPUs- especially before the defect was publicly acknowledged.

If a product does not last because of a defect, then the company should respect their customer's investment by honoring the warranty- or by recalling the product if the defect is found to be common, as with Bumpgate. Nvidia's SEC report[20] shows that they appeared to have this intention, and the company informing Dell[23] and HP[21] of the defect also seem to demonstrate this. In addition, based on the fact that Bumpgate affected some non-Nvidia processors (such as the Xbox 360's ATI graphics processor[3]), Nvidia was likely not fully responsible for the underfill defect. In fact, they alleged in the SEC report that it was their packaging company that caused the problem. However, this did not quell consumers' anger at Nvidia, and a class action lawsuit was filed. Unfortunately, the results of that lawsuit and subsequent settlement left consumers still angry and frustrated at the company- especially those who received insufficient compensation, like those who ended up with a budget laptop to replace their high-end laptop.[30] This only fueled consumer distrust for Nvidia. Although the defect may not have fully been Nvidia's fault, their failure to properly compensate some Class Members when they agreed to settle was unacceptable.

Misdiagnosis/Poor Repair of Faults

There was a lot of speculation among affected consumers as to why so many GPUs were failing, and theories tended to vary between communities for devices. For example, consumers who purchased an Xbox 360 from this era[33] and even some independent repair technicians[34] assumed that the issue was caused by Microsoft using lead-free solder balls- used to connect the Xenos GPU to the motherboard- in order to meet new-at-the-time RoHS standards in the European Union. Many blamed it on the more brittle nature of non-leaded solder balls compared to traditional leaded ones. Others thought it was related to the solder balls' melting point, and that the console getting too hot and literally "desoldering" the GPU. These misconceptions largely faded into obscurity when Microsoft released the Jasper and Falcon revisions of the Xbox 360, and announced their extended warranty on their defective consoles. They were dispelled entirely with the release of Chapter 5 of Power On: The Story of Xbox[3], where hardware engineers for Xbox during this era explained the problem.

With the PlayStation 3, much of the same speculation happened as with the Xbox 360. However, because the defect was never acknowledged as such by Sony, it was far less clear to consumers what exactly was causing the fault in consumers' machines. Long after the PS3 was no longer supported by Sony, this led many retro console and repair enthusiasts to make poorly informed choices in how to attempt to repair their devices. By 2018, many owners were also convinced for some time that the fault wasn't even related to their RSX GPU, but rather, the NEC-Tokin capacitors surrounding it.[35] The reason for the misconception was because Toshiba laptops from the same era had their NEC-Tokins fail prematurely due to a design flaw specific to those laptops. Some general hardware failures can be caused by the PS3's NEC-Tokin capacitors failing (primarily due to age), but Sony had designed the motherboard correctly when placing the NEC-Tokins- so they would not fail prematurely. It was not until 2022-2025 that this misconception was largely corrected amongst the community, and the true defect was identified as likely to be Bumpgate-related.[2]

With the help of Xbox 360 repair and modding enthusiast Josh Davidson (Octal450 on the ConsoleMods Wiki), YouTube user "RIP Felix" performed various experiments to confirm his theory that the PS3's 90nm RSX was affected by Bumpgate. They tested the solder bumps under the 90nm RSX's die to confirm the use of high-lead solder bumps, and also performed a variety of tests on the underfill, comparing it to similar defective and non-defective GPUs from the same era- such as the Xbox 360's GPUs and Nvidia's GPUs. The tests included simply shining an ultraviolet light on the underfill to see the similarities in color and luminescence, poking the underfill of each of the GPUs with a soldering iron at various temperatures to compare the reactions, and even using a UV visual spectrophotometer to visualize the difference between compositions in various underfills. The results strongly support Felix's theory that the PS3's 90nm RSX's defects were due to Bumpgate; each test showed that the 90nm RSX was remarkably similar to known defective GPUs, but distinct from non-defective ones.[15]

A common bad practice between both the Xbox 360 and the PS3 was to reflow the entire motherboard. Even alleged professional repair technicians did this, as shown in BBC's Watchdog segment for the "Yellow Light of Death".[12] However, because this fault was caused by a defect in the GPU, this would only fix the problem temporarily, if at all. In addition, a motherboard is not designed to go through this process more than once (specifically, at the time of manufacture), so this would damage the motherboard over time until it would be impossible to fix the system again.

The only way to permanently fix systems with a Bumpgate-affected GPU is to replace the defective GPU with one that doesn't have the defect. How possible that is, however, depends much on a person's skills, tools, and how easy or difficult it is for regular consumers to repair and modify the system. For example, the PS3 has a modification called "Frankenstein", which makes it possible to replace a defective 90nm RSX GPU with a non-defective 65nm or 40nm GPU from one of the newer PS3s. This modification was inspired by an "official" fix that Sony performed on some faulty PS3s. However, for a person to perform this repair, they would need a BGA rework station (and the skills to use it properly) and a softmodded PS3. A similar modification is also possible for early Xbox 360s, but it requires the same tools and modding experience as the PS3 does. Due to the specialized nature of such modifications, most people will still recommend for consumers to find someone skilled enough to do the modification for them, buy a system that is already modified, or to simply avoid purchasing consoles impacted by Bumpgate.

References

- ↑ 1.0 1.1 Demerjian, Charlie (1 Sep 2008). "Why Nvidia's chips are defective". The Inquirer. Archived from the original on 20 May 2009. Retrieved 1 Jun 2025.

- ↑ 2.0 2.1 2.2 RIP Felix (23 Dec 2022). "A PS3 Story: The Yellow Light of Death". YouTube. Retrieved 2 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 3.0 3.1 3.2 3.3 3.4 3.5 3.6 Xbox (13 Dec 2021). "Power On: The Story of Xbox | Chapter 5: The Red Ring of Death". YouTube. Archived from the original on 13 Dec 2021. Retrieved 4 Jun 2025.

- ↑ 4.0 4.1 4.2 "Affected Models". The NVIDIA GPU Litigation. Archived from the original on 1 Oct 2010. Retrieved 7 Jun 2025.

- ↑ Williams, Rob (29 Sep 2008). "NVIDIA at a Disadvantage Due to their Choice of Solder?". Techgage. Retrieved 1 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Ray, S.; Kiyono, S.; Waite, K.; Nicholls, L. (2006). "Qualification of low-K 90nm Technology Die with Pb-free Bumps on a Build-up Laminate Package (PBGA) with Pb-free Assembly Processes". 56th Electronic Components and Technology Conference: 139–144 – via IEEE.

- ↑ 7.0 7.1 7.2 RIP Felix (15 Jan 2024). "A 360 Story - The RED Ring of Death & the 7th Generation Console War". YouTube. Retrieved 2 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Moore, Peter (2007). "Open Letter From Peter Moore". Xbox. Archived from the original on 23 Oct 2007. Retrieved 4 Jun 2025.

- ↑ Nadaman; et al. (8 Jun 2025). "Xbox 360 - Buying Guide". ConsoleMods Wiki. Retrieved 14 Jun 2025.

{{cite web}}: Explicit use of et al. in:|last2=(help)CS1 maint: url-status (link) - ↑ 10.0 10.1 BBC (18 Sep 2009). "Sony rebuts BBC PlayStation claim". BBC NEWS. Archived from the original on 19 Feb 2025. Retrieved 4 Jun 2025.

- ↑ 11.0 11.1 Martin, Matt (17 Sep 2009). "Sony tackles BBC over 'PS3 failure' report". Gamesindustry.biz. Retrieved 10 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 12.0 12.1 12.2 HelpForPS3 (Reuploader); BBC (17 Dec 2009). "Sony PS3 Yellow Light of Death - BBC". YouTube. Retrieved 3 Jun 2025.

{{cite web}}: CS1 maint: numeric names: authors list (link) CS1 maint: url-status (link) - ↑ 13.0 13.1 Miller, R. (26 Jun 2008). "PS3 graphics chip going 65nm this Fall". Engadget. Archived from the original on 24 Sep 2021. Retrieved 3 Jun 2025.

- ↑ "NVIDIA Playstation 3 GPU 65nm Specs". TechPowerUp GPU Database. Retrieved 3 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 15.0 15.1 15.2 RIP Felix (9 Jun 2025). "A PS3 Story 2: Defending BumpGate Theory". YouTube. Retrieved 10 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 16.0 16.1 Icferrum (2 Feb 2020). "Frankenstein PHAT PS3: CECHA with 40nm RSX". PSX-Place. Retrieved 14 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Mystic (9 Apr 2025). "Sony's PS3 Upgrade They Never Told You About: Official 40nm RSX Frankenstein Console From Sony". YouTube. Retrieved 14 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 18.0 18.1 Derf; Nadaman; et al. (14 Jun 2025). "PlayStation 3 - Buying Guide". ConsoleMods Wiki. Retrieved 14 Jun 2025.

{{cite web}}: Explicit use of et al. in:|last3=(help)CS1 maint: url-status (link) - ↑ 19.0 19.1 19.2 Demerjian, Charlie (9 Jul 2008). "All Nvidia G84 and G86s are bad". The Inquirer. Archived from the original on 10 Jul 2008. Retrieved 7 Jun 2025.

- ↑ 20.0 20.1 20.2 20.3 Burkett, Marvin; United States Securities and Exchange Commission (2 Jul 2008). "Form 8-K". SEC. Retrieved 8 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 21.0 21.1 21.2 HP (2008). "HP Pavilion dv2000/dv6000/dv9000 and Compaq Presario v3000/v6000 Series Notebook PCs - HP Limited Warranty Service Enhancement". HP Customer Care. Archived from the original on 10 Jul 2008. Retrieved 8 Jun 2025.

- ↑ BlueScreenDeath; Menchaca, Lionel (23 Sep 2008). "Dell Warranty Extension Due to Nvidia Defect". Dell Community. Retrieved 8 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 23.0 23.1 23.2 Meyer, David (19 Aug 2008). "Dell extends warranties after GPU fault". ZDNet. Retrieved 8 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 24.0 24.1 Foresman, Chris (10 Oct 2008). "Apple: NVIDIA chips to blame for MacBook Pro video problems". Ars Technica. Retrieved 8 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Buchanan, Matt (10 Oct 2008). "Apple Confirms Failing Nvidia Graphics Cards in MacBook Pros, Offers Free Repairs and Refunds". Gizmodo. Retrieved 7 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Apple Support (18 Nov 2014). "MacBook Pro: Distorted video or no video issues". Apple. Archived from the original on 2 Dec 2014. Retrieved 7 Jun 2025.

- ↑ Buchanan, Matt (3 Jul 2008). "Lots of Nvidia Laptop Graphics Cards Are Overheating, Dying". Gizmodo. Retrieved 7 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ 28.0 28.1 Hruska, Joel (16 Jul 2008). "NVIDIA denies rumors of faulty chips, mass GPU failures". Ars Technica. Retrieved 8 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ "Frequently Asked Questions - What can I get from the settlement?". The NVIDIA GPU Litigation. 2010. Archived from the original on 1 Sep 2010. Retrieved 13 Jun 2025.

{{cite web}}:|archive-date=/|archive-url=timestamp mismatch; 1 October 2010 suggested (help) - ↑ 30.0 30.1 DeCarlo, Matthew (3 May 2011). "Customers get shafted in Nvidia class action suit". TechSpot. Retrieved 13 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Sanders, Kathleen; Casamassina, Matt (14 Sep 2006). "US Wii Price, Launch Date Revealed". IGN. Retrieved 10 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Surette, Tim (17 Aug 2005). "Xbox 360 pricing revealed: $299 and $399 models due at launch". GameSpot. Archived from the original on 5 Jun 2013. Retrieved 10 Jun 2025.

- ↑ Enever, Liam (1 Oct 2017). "Why has my got the red ring of death (sic)". iFixIt Answers Forum. Retrieved 4 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ "Xbox 360 Red Ring of Death: Why Lead-Free Solder or Solder Failure Are the Problem". The Electronic Fix. 8 Apr 2014. Retrieved 4 Jun 2025.

{{cite web}}: CS1 maint: url-status (link) - ↑ Naked_Snake1995 (15 Jul 2019). "(Research/Experimental) - NEC/TOKIN Capacitors Replacement - YLOD". PSX-Place. Retrieved 4 Jun 2025.

{{cite web}}: CS1 maint: numeric names: authors list (link) CS1 maint: url-status (link)